ABOUT HVEA

HVEA was established in Malaysia in 1993, with a group of over 2,500 employees, initially specializing in particleboard manufacturing. As the Group continued to grow, the business gradually expanded into furniture manufacturing (HeveaPac, 2001) and was listed in Malaysia in 2005. Following the environmental philosophy of sustainable development, a HeveaGro subsidiary was established in 2017 to utilize the bark from the production process for edible mushroom cultivation.In 2022, HVEA EVERVEA undertook a comprehensive brand strategy upgrade, identifying the upgrade from a veneer board brand to a veneer brand, and laying out the global market with a veneer board brand. Through the veneer manufacturing and edible fungus planting will rubber forestry resources better application, so that rubber wood in the end of the rubber cutting period to give full play to its economic value, reconstructing resources and capabilities, innovative ecological into the concept of sustainable development, leading the industry to new changes in environmental protection and health.

In 2023, HVEA set up a design team in Europe, independent research and development of the finish texture, while building a production plant in China, the introduction of Germany's advanced Wincanton synchronous pattern production line, to overcome the synchronous pattern technology, with precise pressure adjustment and sensitive temperature control system, to ensure that the best presentation of the effect of the finish panel, strict control of product quality, finish design excellence, to create a world of fashionable top veneer products. Strict control of product quality and excellence in finish design, to create the world's top fashion veneer products.

In 2023, HVEA set up a design team in Europe, independent research and development of the finish texture, while building a production plant in China, the introduction of Germany's advanced Wincanton synchronous pattern production line, to overcome the synchronous pattern technology, with precise pressure adjustment and sensitive temperature control system, to ensure that the best presentation of the effect of the finish panel, strict control of product quality, finish design excellence, to create a world of fashionable top veneer products. Strict control of product quality and excellence in finish design, to create the world's top fashion veneer products.

-

Growth cycle up to 30 years

30年

-

Large diameter rubber wood

100%

-

Forest area in Malaysia

300000hm²

-

Annual output of production line

525000m³

Resource Advantage

HVEA rubber plantations cover a vast area of 300,000 hectares of forested land under its own ownership. HVEA rubber plantation covers a vast area of 300,000 hectares of forest land, which provides HVEA with a strong and continuous support of resources, and a perfect management system of felling-transportation-storage-use, which guarantees the purity of raw materials and makes the panels free from any peculiar odor. The raw material for the base material is made from large caliber rubberwood with a growth cycle of more than 30 years in its own rubber plantation. Refuse to add waste materials, the density of the base material particles is uniform, tough and stable, with a strong grip on nails.

Manufacturing Advantage

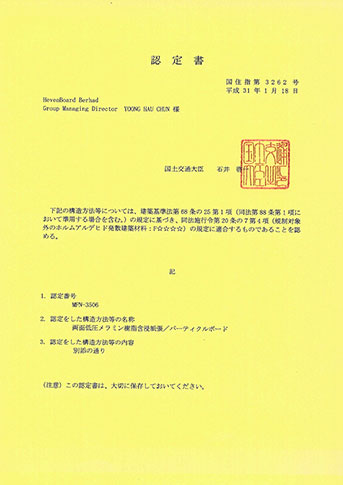

HVEA substrate selection of international leading technology Dieffenbacher production line, planer sheet form thin, long, uniform, through the longitudinal and transverse mesh pavement, while using 45 meters length of customized Dieffenbacher continuous press, 700KGS/m3 pressure above the continuous flat pressure, the average single line size is much higher than the industry average, the integration of low-formaldehyde environmental protection standards of the adhesive, to prolong the plate pressing time, to give the glue adequate Reaction time, thereby increasing the adhesive force, help plate shaping, enhanced deformation resistance, static curvature and nail holding power. Made of high-end boards with no impurities, more stable structure, better load-bearing, less deformation, and meet the environmental standards of JS certification F ☆☆☆☆ grade boards.

Research and Development Advantage

German Winkler Synchronized Contrast Lamination

HVEA YIVEA veneer starts from a high starting point and high standard, and fully introduces German Wincanton synchronous counter-pressure pasting equipment with precise pressure adjustment and sensitive temperature control system, which redefines the high standard process with its superior performance and ensures the best presentation of veneer effect. On this basis, HVEA YIVEA layout of the national market, standardization of standardized finish product quality, high standards, high efficiency, high quality to promote the development of the veneer industry, to provide customers with more reliable and more assured service.

HVEA YIVEA veneer starts from a high starting point and high standard, and fully introduces German Wincanton synchronous counter-pressure pasting equipment with precise pressure adjustment and sensitive temperature control system, which redefines the high standard process with its superior performance and ensures the best presentation of veneer effect. On this basis, HVEA YIVEA layout of the national market, standardization of standardized finish product quality, high standards, high efficiency, high quality to promote the development of the veneer industry, to provide customers with more reliable and more assured service.

-

Resource Advantage

-

Manufacturing Advantage

-

Research and Development Advantage

HVEA Yiweiya Malaysia team

2024-2025

HVEA events

HVEA X Boloni

2024 Continuing to be a “pervert” and renewing the ten-year contract, fully upgraded to the JIS F★★★★ level.

HVEA X Boloni

2024 Continuing to be a “pervert” and renewing the ten-year contract, fully upgraded to the JIS F★★★★ level.

HVEA X Boloni

2024 Continuing to be a “pervert” and renewing the ten-year contract, fully upgraded to the JIS F★★★★ level.

-

2023Re-establishment of an active layout for the Chinese market and determination of the layout of the Chinese market in the form of veneer panels

-

2017Establishment of the subsidiary HeveaGro

Utilizing sheet residuals for edible mushroom cultivation -

2005Listed on the Main Board of Bursa Malaysia Securities Berhad

Listing Code: 5095 -

2001Establishment of a subsidiary, HeveaPac, to provide assembled furniture manufacturing & sales

-

1996HVEA's second production line is in operation with an annual capacity of 525,000 m³.

-

1993HVEA's first production line completed, specializing in particleboard products

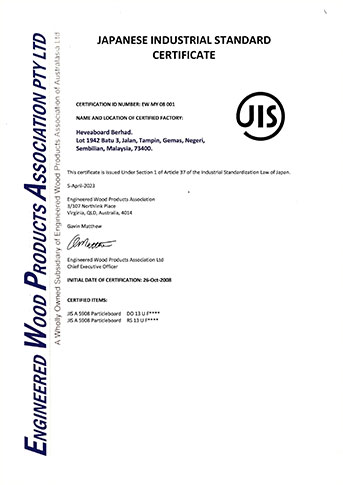

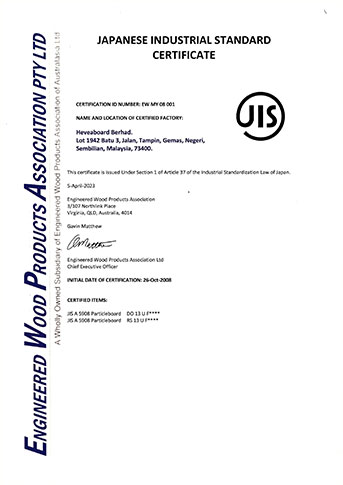

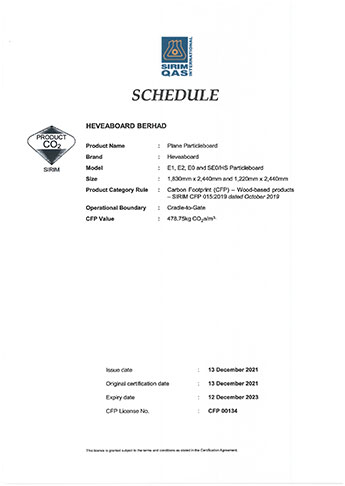

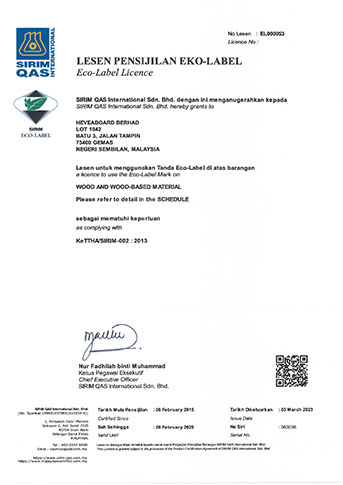

Certificate

The company has a complete quality management system such as IS050001.1IS0 14001.150 9001 and the Singapore Green Label Certification, FSC Forest System Certification for environmental concern, PEFC Forest Certification, CARB Certification for compliance with applicable emission standards, and so on.

F★★★★ environmentally friendly grade veneer boards certified by the Japanese industry (U5S), making HeveaBoard a recognized manufacturer of Soka boards by the world's most recognized industrial organizations.

ECO-LABEL certified by SIRIMOAS, ASEAN Energy Management Best Award 2014, Outstanding Exporter Award (Trade Association Group) Productivity Award Special Award from the International Productivity Council (NPC), and so on.

In the future, HVEA will work with its global partners to create more environmentally friendly and better quality household products, and at the same time spare no effort in reducing carbon dioxide emissions and increasing the use of clean energy and other social responsibilities to achieve excellence.

Slide down to view certificates

- T / 0571-8811 4008

- A / No. 555 Huancheng North Road, Deqing County Development Zone, Huzhou City, Zhejiang Province

- F/ 0571-8811 3267

-

Advantages

Search for the product you are looking for

Copyright @ 2025 ALL LIMITED Zhejiang Yiweiya Wood Industry Co., Ltd. Zhejiang ICP No. 2023031895

Support:80com